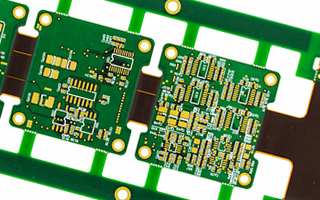

Flex and Rigid Flex PCBs

Our flex and rigid-flex circuit board solutions are custom designed for many top tier OEMs. Manufactured with dependable reliability, our flexible circuits are built to withstand the rigors of aerospace, medical, and military applications. As a high reliability replacement for wire and wire harness assemblies, flex circuits provide a significant cost savings with no reduction in performance

FLEX & RIGID-FLEX CIRCUIT BENEFITS

Flex and rigid-flex circuit technology provides significant additional capabilities above and beyond other available interconnect methods. These include reduced packaging requirements, improved reliability, improved shock and vibe performance, improved high-speed signal performance, improved harsh environment performance, and reduced cost opportunities. These items, either individual or combined, provide valid solutions that solve many of the design challenges experienced throughout the electronics industry.

Single-Layer Flex Circuit

- IPC 6013 - Type 1

- Description:

- One conductive copper layer bonded between two insulating polyimide layers

- Example construction: coverlay/copper/flex core

- Configurations:

- Single-sided access, dual-sided access, unsupported fingers

- Flex Core Materials:

- Standard thicknesses: 1/2 mil to 3 mil in either adhesive or adhesiveless constructions

- Standard copper thicknesses: 1/3 oz to 2 oz in rolled annealed or electro deposited formats

- Coverlays:

- Standard thickness: 1/2 mil to 2 mil polyimide, with 1/2 mil to 2 mil epoxy or acrylic adhesive

- Stiffeners:

- Component support or ZIF connector thickness requirments

- Materials: polyimide, FR4, stainless steel, aluminum

- PSA (pressure sensitive adhesives) available for attachment purposes

- EMI/RF shielding films available

- Applications:

- Suitable for either bend to fit or dynamic flex applications

Double-Sided Flex Circuit

- IPC 6013 - Type 2

- Description:

- Two conductive copper layers with an insulating polyimide between and external polyimide insultaing layers

- Plated through-holes provide circuit connection between layers

- Example construction: coverlay/copper/flex core/copper/coverlay

- Configurations:

- Single-sided access, two-sided access, castelated holes

- Flex Core Materials:

- Standard thicknesses: 1/2 mil to 4 mil in either adhesive or adhesiveless contructions

- Standard copper thicknesses: 1/3 oz to 2 oz in rolled annealed or electro deposited formats

- Coverlays:

- Standard thickness: 1/2 mil to 2 mil polyimide with 1/2 mil to 2 mil epoxy or acrylic adhesive

- Stiffeners:

- Component support or ZIF connector thickness requirments

- Materials: polyimide, FR4, stainless steel, aluminum

- PSA (pressure sensitive adhesives) available for attachment purposes

- EMI/RF shielding films available

- Applications:

- Bend to fit and dynamic flex applications (construction dependant)

- High-speed controlled impedance in surface micro strip configuration

Multi-Layer Flex Circuit

- IPC 6013 - Type 3

- Description:

- Three or more flexible conductive layers with flexible insulating layers between each one and external polyimide insulating layers

- Plated through-holes provide circuit connection between layers

- Example construction: coverlay/copper/flex core/copper/adhesive/flex core/copper/coverlay

- Configurations:

- Single-sided access, two-sided access, castelated holes

- Flex Core Materials:

- Standard thicknesses: 1/2 mil to 4 mil in either adhesive or adhesiveless contructions

- Standard copper thicknesses: 1/3 oz to 2 oz in rolled annealed or electro deposited formats

- Coverlays:

- Standard thickness: 1/2 mil to 2 mil polyimide with 1/2 mil to 2 mil epoxy or acrylic adhesive

- Stiffeners:

- Component support or ZIF connector thickness requirments

- Materials: polyimide, FR4, stainless steel, aluminum

- PSA (pressure sensitive adhesives) available for attachment purposes

- EMI/RF shielding films available

- Applications:

- Bend to fit only

- High-speed controlled impedance in surface micro strip or stripline configurations

Rigid-Flex Circuit

- IPC 6013 - Type 4

- Description:

- Two or more conductive copper layers with either flexible or rigid insulation material as insulators between each layer

- Plated through-holes extend through both rigid and flexible layers

- Coverlay selectively applied to flex layers in flexible areas only

- Blind and buried vias available

- Example construction: Soldermask/copper/FR4/copper/flex core/copper/FR4/copper/soldermask

- Configurations:

- 1 or more flexible layers; multiple flex layers in either bonded or air gap configuration

- 1 or more rigid layers

- Flex Core Materials:

- Standard thicknesses: 1/2 mil to 4 mil in either adhesive or adhesiveless constructions

- Standard copper thicknesses: 1/3 oz to 2 oz in rolled annealed or electro deposited formats

- Coverlays:

- Standard thickness: 1/2 mil to 2 mil polyimide, with 1/2 mil to 2 mil epoxy or acrylic adhesive

- Stiffeners:

- Component support or ZIF connector thickness requirements

- Materials: polyimide, FR4, stainless steel, aluminum

- Rigid Materials:

- 180 TG FR4, low flow prepreg

- EMI/RF shielding films available

- Applications:

- Suitable for either bend to fit or dynamic flex applications (1-2 flex layers only)

- High-speed controlled impedance in surface micro strip or stripline configurations