CNC Machining

&

Sheet Metal Fabrication

Our Partners quick turn CNC machining utilizes 3 and 5 axis, conventional and high-speed CNC equipment with the newest CAM Software. This is the most cost-effective process for producing prototypes, patterns and short-run production parts. We can manufacture machined parts from solid aluminum, steel, plastic, composites, and many others giving us the capability to machine a variety of designs with high precision, that are geometrically complex, and milled components with very tight tolerances with minimum tooling.

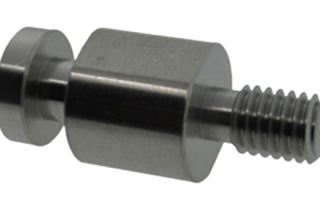

CNC Milling and Turning

With state-of-the-art CNC milling machines, we can tackle one-piece prototypes, quick turn production runs or customer tooling. With 10 different CNC milling machines which are built for precise manufacturing and repeatability they are perfect for rapid prototyping and low-to-high volume production runs

Our CNC turning machines with milling operation saves time by eliminating costly setup time, and we mill parts on multi-axis CNC lathes equipped with live tooling. Live tooling lathes can perform many different operations, including facing, threading, knurling, drilling, boring, reaming, and taper turning.

5-axis CNC machines can produce parts with complex geometries and increase productivity by minimizing the number of machine setups. The dual-axis trunnion table can position parts to nearly any angle for 5-axis (3+2) machining or provide full simultaneous 5-axis motion for contouring and complex CNC machining.

We make hard tooling from a variety of materials (hardened or pre-hardened steel, aluminum, and/or beryllium-copper alloy) to suit your budget, order volume, and time to production.

Sheet Metal Fabrication

We offer a full array of precision sheet metal fabrication and machining capabilities coupled with the added value of electro-mechanical assembly and integration. The list is long but the bottom line is: If you can conceptualize an item made out of any type of metal, we have the capability to make it a reality. We have invested in state-of-the art facilities as well as equipment to ensure that our customers' parts are made to specification and delivered on time.

Automation has allowed us to increase manufacturing output with better results. Faster, Increased Accuracy, Higher Volumes, Streamlined, Efficient, Reliability are just a few results from our automation. Our Amada press brake with the Automatic Tool Changer allows us to reduce set up times from hours to minutes significantly increasing production time. Robotic Mig and Tig welders increase throughput and accuracy. Our powder coat line has an automated 5 stage iron phosphate wash line allowing us to properly wash, clean, and treat parts prior to powder application. Better prep equals better results.